With an annual production capacity of hundreds of thousands of parts/sets, it can fulfill both large-volume orders and urgent delivery requirements.

Sheet metal stamping is a manufacturing process that involves the use of dies and presses to transform flat metal sheets into specific shapes. This method is widely utilized across various industries due to its efficiency and ability to produce precise parts with high repeatability.

Forging is a processing method that uses forging machinery to exert pressure on metal blanks to cause plastic deformation to obtain forgings with certain mechanical properties, shapes and sizes. Casting is a processing method in which metal is melted and poured into a pre-made mold. After condensation and cleaning, the required workpiece or blank is obtained.

Welding is a forming method that uses heating, pressurization or a combination of both to create an atomic bond between two separate objects and connect them into one. Welding processes are mainly divided into three categories: fusion welding, pressure welding and brazing. And welding processes are widely used in various fields, such as automobiles, ships, aircraft, high-speed rail and other high-precision manufacturing fields. Sheet metal stamping is a manufacturing process that involves the use of dies and presses to transform flat metal sheets into specific shapes. This method is widely utilized across various industries due to its efficiency and ability to produce precise parts with high repeatability.

Wire forming products are a general term for elastic elements with different shapes and complexities and certain spring functions, which are made by bending various metal wires such as steel wire and iron wire. According to different usage environments and requirements, wire forming products need to be produced using some metal wires with different characteristics.

Vacuum coating is an important aspect in the field of vacuum applications. It is based on vacuum technology, uses physical or chemical methods, and absorbs a series of new technologies such as electron beams, molecular beams, ion beams, plasma beams, radio frequencies, and magnetrons. It provides scientific Research and practice provide a new process for thin film preparation. Simply put, the method of evaporating or sputtering metals, alloys or compounds in a vacuum, solidifying and depositing them on the workpiece (block, substrate or matrix) is called vacuum coating.

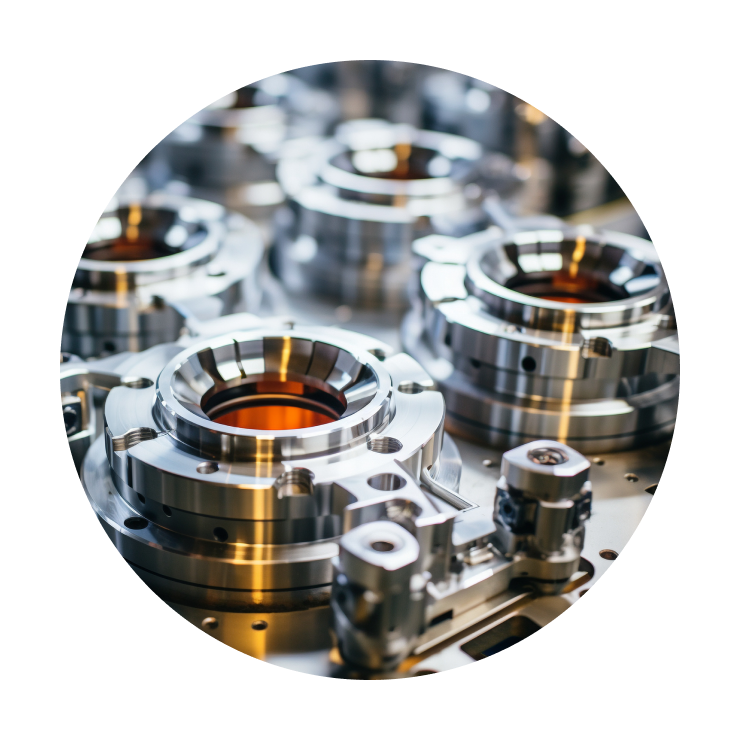

Capable of customizing various precision mechanical parts according to customer needs

Qingdao Shiji Pinyang Machinery Manufacturing Technology Co., Ltd. is a professional enterprise specializing in the research and development, design, and subcontracting of precision mechanical parts. Established in 2015, the company is located in Daxin Industrial Park, Qingdao, China, covering an area of over 5,000 square meters. It boasts advanced production equipment and a rigorous quality management system.

Annual Production Capacity

Covering An Area

Quality Management System

With the advancements in automation and intelligence technology, precision machining has achieved a high level of automation and intelligence. By employing numerical control technology, automated inspection, and other methods, the processing process can be precisely controlled and optimized, leading to increased efficiency and reduced production costs.

One of the primary features of precision machining is its high degree of accuracy. By utilizing advanced machining equipment and processes, precise control over part tolerances can be achieved, often reaching micrometer or even nanometer levels. This level of precision is essential for industries such as aerospace, aviation, and precision instrumentation.

Precision machining exhibits broad applicability, capable of integrating with various materials and processing techniques to create parts of diverse shapes, sizes, and compositions. This flexibility allows precision machining to cater to the needs of diverse industries and applications.

Precision machining enables precise control over the surface quality of parts. By optimizing processing parameters and techniques, extremely low surface roughness and highly consistent finishes can be achieved. This high surface quality is crucial for applications in optics, electronics, and medical devices.

Precision machining emphasizes environmental protection and sustainable development. By adopting advanced equipment and processes, waste and emissions during processing can be minimized, reducing the impact on the environment.

Customer provides drawings/samples → Technical team evaluates process feasibility within 24 hours → Provides quotations and establishes orders simultaneously.

Material and processing method selection → Sends the "Process Confirmation Form" for client approval.

Full-process CNC machining → Surface treatment (e.g., oxidation/electroplating) → Real-time updates of processing progress via photos.

After passing comprehensive quality inspection, products are packaged with rust-proof measures → Inspection reports are provided → Products dispatched via logistics (on-site inspection at destination supported).

Qingdao Shiji Pinyang Machinery Manufacturing Technology Co., Ltd. is a professional enterprise specializing in the research and...

Qingdao Shiji Pinyang Machinery Manufacturing Technology Co., Ltd. is a professional enterprise specializing in the research and...

Qingdao Shiji Pinyang Machinery Manufacturing Technology Co., Ltd. is a professional enterprise specializing in the research and...