About this product:

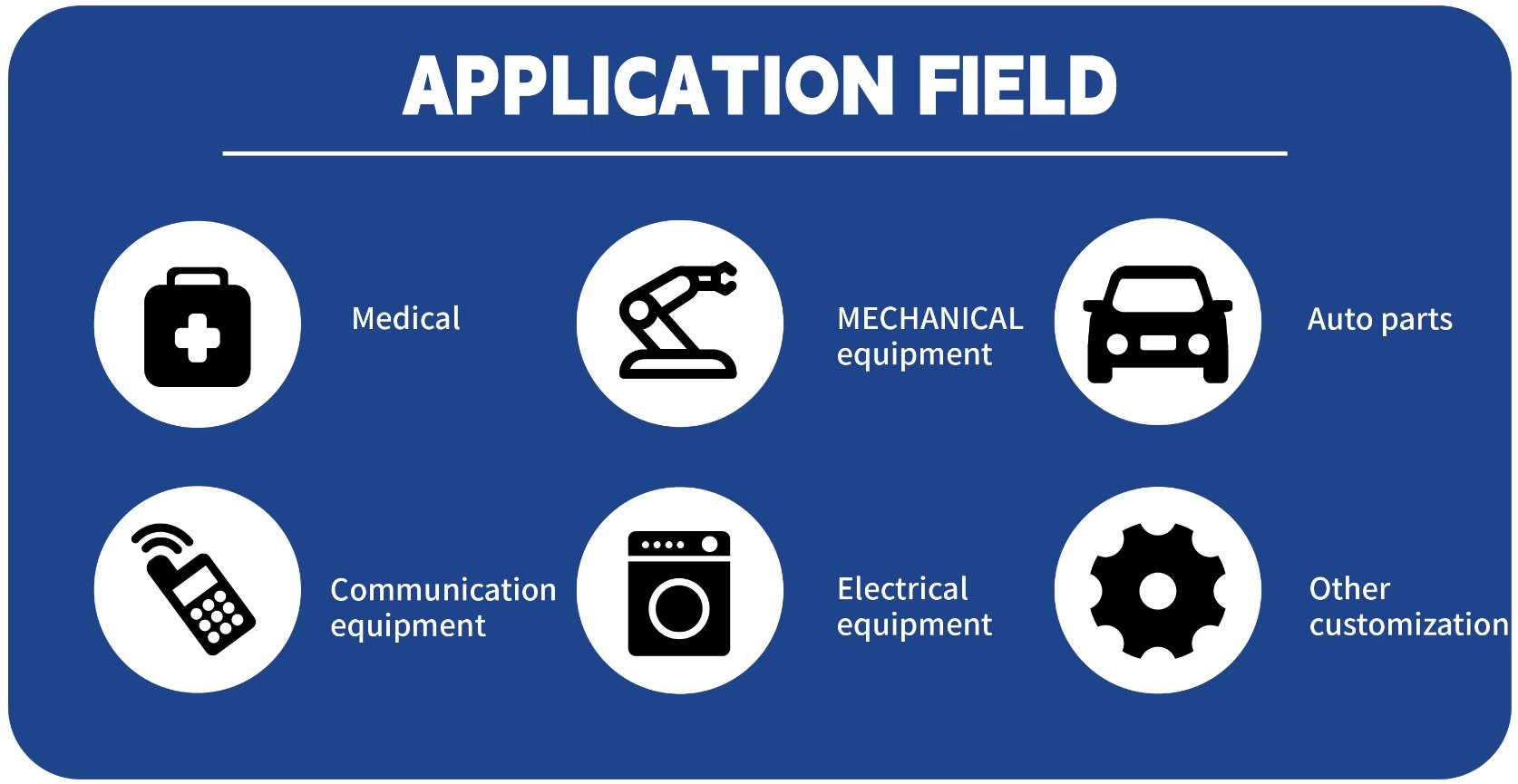

• Customizable Machining Services: Our custom CNC machining services cater to various materials, including aluminum, brass, stainless steel, and more, allowing for a wide range of applications.

• Precision Machining Capabilities: We offer precision machining services, including drilling, milling, and wire EDM, to meet the specific needs of our clients, such as the user's requirement for precision parts.

• Micro Machining Expertise: Our team specializes in micro machining, enabling the production of intricate and complex parts with high precision and accuracy.

• Custom Surface Treatment Options: We provide various surface treatment options, including brushing, to meet our clients' specific requirements, as mentioned by the user, for example, a customer's requirement for brushed surface finish.

• Fast and Reliable Delivery: Our standard delivery time is 3-15 days, ensuring that our clients receive their custom-made parts efficiently, meeting their needs for timely production and delivery.

| Place of origin | Qingdao, China |

| Brand name | Speed worth |

| Product name | CNC machining parts |

| Material | ZINC, ALLOY, Titanium, Stainless steel, Steel |

| Standard | Non standard |

| Size | Drawing |

| MOQ | 100pcs |

| Delivery time | 3-15 days |

| OEM | OEM service offered |

| Packing | Cartons+plastic bags |

Not only did they help me alter my design to make it more cost effective to manufacture, they were very communicative, fast, and the product looks amazing! I will definitely be using them in the future!

Very reliable and communitive, Quality of goods is superb and always very pleased with the quality, any issues raised are always rectified too.